Early in the morning on April 24, an ethanol train derailed, exploded, and burned near Fort Worth, Texas, reportedly destroying a horse stable, killing three horses, and causing the evacuation of nearby homes. According to early reports, 20 tank cars left the tracks, with at least five rupturing and burning.

While specific details have not yet been released, it appears to be a unit train of ethanol using the federally mandated DOT-117R tank cars, based on the images showing tank car markings. This is now the third accident in North America involving the upgraded DOT-117R tank cars, all resulting in major spills of either oil or ethanol.

BREAKING: A live look at a train derailment in south Fort Worth. Officials say the train was carrying cars with ethanol. #KHOU11 #HTownRush https://t.co/HZe0tpR5sK

— KHOU 11 News Houston (@KHOU) April 24, 2019

This latest fiery derailment highlights the dangers to the estimated 25 million people living within the blast zone along rail lines across North America. While this incident had no human fatalities, the oil train disaster in Lac-Mégantic, Quebec, in 2013 killed 47 people, devastating the small Canadian town. As I’ve exhaustively reported, the same risk factors for hauling oil by rail, and increasingly, ethanol, are still in place years after the Lac-Mégantic disaster.

In Texas, first responders were quickly on the scene and able to contain the fire, preventing the situation from worsening. When ethanol rail tank cars are involved in fires, the unpunctured tanks can explode as the fire increases the temperature and pressure in the full tanks.

For example, after a BNSF train derailed in Montana in August 2012, eight of the 14 cars carrying ethanol caught fire, resulting in an explosion and the signature “bomb train” mushroom cloud–shaped ball of fire.

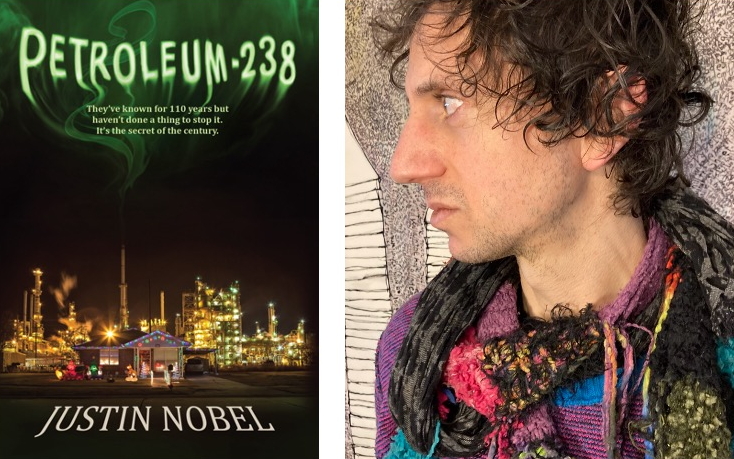

Video: Fort Worth ethanol train derailment. Credit: Glen E. Ellman

Ethanol Industry Adopting Risky Oil Train Practices

In 2016 DeSmog published a series of articles analyzing why oil trains were derailing at over twice the rate of ethanol trains. Likely contributing factors included the fact that the derailing oil trains were longer and heavier than ethanol trains.

The oil industry was moving oil using “unit trains,” which are long trains dedicated to a single commodity, while the ethanol industry was using shorter trains. The majority of ethanol was shipped as part of manifest trains, carrying multiple types of cargo and not just ethanol.

As part of the analysis, DeSmog found that derailing ethanol trains tended to be longer trains of 100 or more cars.

However, longer trains are more profitable, and in 2016 the ethanol industry noted it intended to follow the lead of the oil industry and begin to move more ethanol via long unit trains. This announcement led to the following conclusion in the 2016 DeSmog series:

“Based on the ethanol industry’s interest in using more unit trains for ‘efficiency,’ and the fact that it is allowed to transport ethanol in the unsafe DOT-111 tank cars until 2023, perhaps it won’t be long before ethanol trains are known as bomb trains too.”

And while the DOT-111 tank cars are less robust than the DOT-117R tank cars, both have a history indicating neither are safe to move flammable liquids in unit trains. And DOT-117R tank cars are heavier than DOT-111s, adding another factor that increases chances for train derailment.

Bomb Train Risks Continue to Grow

After a string of oil trains filled with volatile crude oil from North Dakota’s Bakken Shale derailed and exploded in 2013 and 2014, there was a push for new safety regulations for trains carrying flammable materials including crude oil and ethanol.

In 2015, the U.S. Department of Transportation released new regulations, which, as DeSmog noted at the time, were a big win for the oil and rail industries and their lobbyists. While touted as increasing safety, these watered-down rules did not address the trains’ known risk factors or require the oil and rail industries to implement proven safety technologies. The one requirement in the new 2015 regulations that would have greatly improved safety mandated that railroads transition to modern braking systems. That requirement has since been repealed.

The rail industry frequently calls the upgraded tank cars, which include DOT-117Rs and were required by federal regulators, a safety improvement. However, in the first two derailments involving the new cars, those purportedly safer tank cars led to major oil spills. One of those occurred in February in Manitoba, Canada, and now the Fort Worth derailment appears to represent a third example of these upgraded rail cars’ failed safety.

In 2014 during rail safety discussions, the rail industry was recommending using much more robust tank cars — known as “pressure cars” — to move the volatile crude oil implicated in oil train explosions, but federal regulators did not incorporate the recommendation into the final rules. That is why oil and ethanol continue to be moved in rail cars that fail and lead to large leaks and fires during derailments.

In Utah a train carrying propane in pressure cars recently derailed, highlighting the risk of even those more robust tank cars. That derailment caused a propane leak, and hazmat experts decided the safest thing to do was detonate the tank cars, a situation possible when in rural Utah. However, health experts were concerned about the impact on air quality for local residents.

Despite the many examples of the risks of moving these flammable materials by rail, President Trump recently issued an executive order mandating federal regulators allow moving liquefied natural gas (LNG) by rail as soon as next year.

These risks are why a group of people were just arrested for blocking oil train tracks in Oregon. And why legislators in the state of Washington have passed legislation requiring oil be stabilized — to make it less volatile and likely to ignite — prior to its loading on rail tank cars for shipment. Several states also are looking at passing laws requiring two-person crews for freight trains to improve safety. One of the factors cited in the deadly Lac-Mégantic oil train disaster was that the train was operated by a single person.

States are moving to address these very real, well-documented, and preventable risk factors because the U.S. federal government has fallen short in mitigating those risks to American communities from the oil and rail industries. These regulatory shortcomings, which began under President Obama’s administration, have only intensified under the Trump administration’s anti-regulatory approach. With the prospect of LNG trains in the near future — along with record amounts of oil trains coming from Canada to U.S. ports and refineries — the risks of “bomb train” accidents (the nickname bestowed by nervous rail operators) continue to grow.

Main image: Screen shot of emergency personnel watching an ethanol train burn near Fort Worth, Texas. Credit: Glen E. Ellman

Subscribe to our newsletter

Stay up to date with DeSmog news and alerts